MK Party/ActionSA supporters confident of good showing in by-election

Supporters of the newly formed uMkhonto weSizwe Party and ActionSA believe their parties will do

IEC encourages active citizenry starting at school level

This an annual programme done by the department in partnership with the IEC.

Man City players on two-day chill-out, says Guardiola

Manchester City players are “in the fridge” for two days as they try to deal with the

Ekurhuleni is the ground zero for the doomsday coalition: Steenhuisen

Steenhuisen made the comments in Springs today.

Kenyan military aircraft crashes: Government

The injured soldiers have been taken to hospital, the source said.

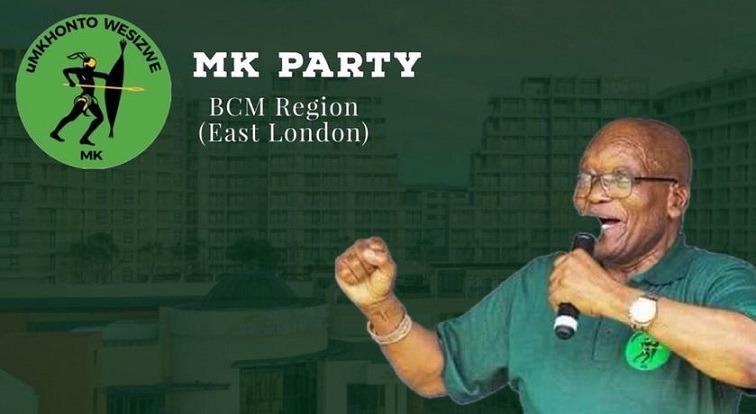

Zuma’s face to be on ballot

The IEC has confirmed that former President Jacob Zuma’s photo will be displayed on the voting

Fall of Myanmar town to rebels sends people fleeing into Thailand

Thailand’s foreign minister said on Friday his government was preparing for an influx of refugees.

Ten Hag warns fans against tragedy chanting when Man U host Liverpool

United are sixth in the standings after losing 4-3 at Chelsea on Thursday at Stamford Bridge.

IEC warns against violence

IEC chairperson Mosotho Moepya has warned against the incitement of violence in the upcoming

Parties to pledge nonviolence during election code signing

Parties are expected to vow against political violence directed at other parties and the IEC during

Parties contesting elections expected to sign electoral code

Political Parties contesting the 29 May elections are expected to sign the electoral code of conduct

UK royal Kate says she is having chemotherapy after cancer discovery

Kate said subsequent tests had revealed cancer had been found.

Last-gasp goals earn Chelsea FA Cup quarter-final win over Leicester

Chelsea had looked in full control at halftime.

Over 70 striking eThekwini workers served with misconduct notices

They have been given 10 days to make submissions on why they should not be dismissed.

Three killed in bus accident near Elysium in KZN

The patients were treated at the scene and transported to hospital for further care.

DA calls on new JEMS Chief to improve firefighting capabilities

The DA’s Michael Sun says Emergency Services responders are working under difficult conditions.

‘Young people are a resource rather than an obligation’

Presidential Youth Employment Initiative boosted with R7.4 billion.

MPs vote in favour of Motata being impeached

Motata becomes the second judge to be impeached today.

India crush England by 434 runs to go 2-1 up in series

India had been in the box seat since grabbing a handy first-innings lead.

Karoo towns in darkness for almost two weeks due to storm damage

The towns which include Sutherland, Lainsburg and Fraserburg.