The US National Transportation Safety Board (NTSB) said late on Monday it could not yet tell whether a recovered cabin panel that blew off an Alaska Airlines Boeing 737 MAX 9 plane in mid-air last week had been properly attached.

The comments came after Alaska Airlines and the other US 737 MAX 9 operator, United Airlines , said on Monday they had found loose parts on multiple grounded aircraft, raising new concerns among industry experts about how Boeing’s best-selling jet family is manufactured.

The Federal Aviation Administration (FAA) grounded 171 MAX 9 planes on Saturday after a panel called a door plug blew off the Alaska Airlines flight not long after taking off from a Portland, Oregon, airport on Friday, forcing pilots to scramble to land the plane safely.

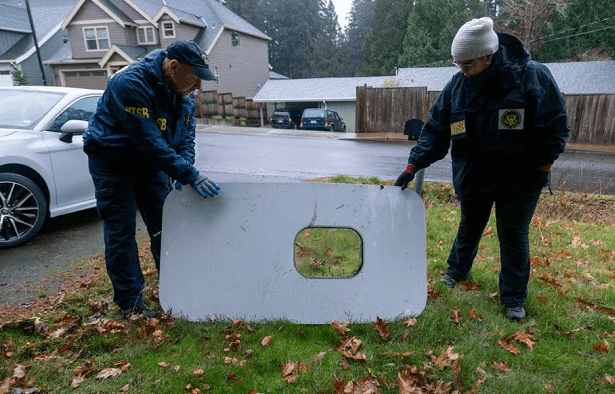

The panel, which covers an optional exit door used by airlines that have denser seating configurations, was recovered on Sunday by a Portland schoolteacher who found it in his backyard.

The NTSB “has not yet recovered the four bolts that restrain it from its vertical movement,” NTSB engineer Clint Crookshanks told reporters at a briefing in Portland. “And we have not yet determined if they existed there.”

The door plug is further fastened in place by “stop fittings” at 12 different locations along the side of the plug and the door frame. Those components hold the door plug in place and prevent it from being pushed out of the aircraft.

“The door translated up and disengaged from the stops, which then fractured the fittings,” Crookshanks said.

Alaska Airlines makes emergency landing

INSPECTION GUIDELINES

NTSB Chair Jennifer Homendy said her agency’s focus was on the accident plane, but it would not hesitate to make broader safety recommendations if needed as its investigation progressed.

There are still ongoing discussions between Boeing, the FAA and the US airlines on precise inspection guidelines for the other 737 MAX 9 planes in their fleets.

Before the NTSB briefing, Alaska Airlines said initial reports from its technicians indicated some “loose hardware” was visible on some aircraft in the relevant area when it conducted checks.

It was waiting for final documentation from Boeing and the FAA before formal inspections could begin.

United said its preliminary checks found bolts that needed tightening on several panels.

The disclosures heightened concerns about the production process of the MAX 9 jets that have been grounded.

A source familiar with the matter said United has so far found close to 10 aeroplanes with loose bolts during its preliminary checks, up from an initial five first reported by industry publication The Air Current, and the figure may increase.

Boeing said it was staying in close contact with MAX 9 operators and would help customers address any findings during inspections.

Any prolonged concerns may increase pressure on Boeing, which has suffered from numerous production issues since a wider grounding of the 737 MAX family in March 2019 that lasted 20 months after two deadly crashes killed 346 people.

Boeing shares sank 8% on Monday.

Once the final process is approved by the FAA, inspections are expected to take several days, forcing the cancellation of numerous flights.

Alaska Airlines cancelled 141 flights, or 20% of its scheduled departures, on Monday after grounding its 65 MAX 9s. The carrier said travel disruptions were expected to last through at least mid-week.

United, which has grounded its 79 MAX 9s, cancelled 226 flights on Monday, or 8% of its scheduled departures.

The FAA said planes would remain grounded “until operators complete enhanced inspections which include both left and right cabin door exit plugs, door components, and fasteners.”